What specific role does quilting play in hotel mattress protectors? How does it help enhance the durability and usefulness of a mattress protector?

The quilting process in hotel mattress protectors helps to strengthen the structure, improve durability, enhance stability, beautify the appearance and facilitate maintenance, thereby enhancing the durability and practicality of the mattress protector, providing guests with more comfort and A reliable sleeping environment.

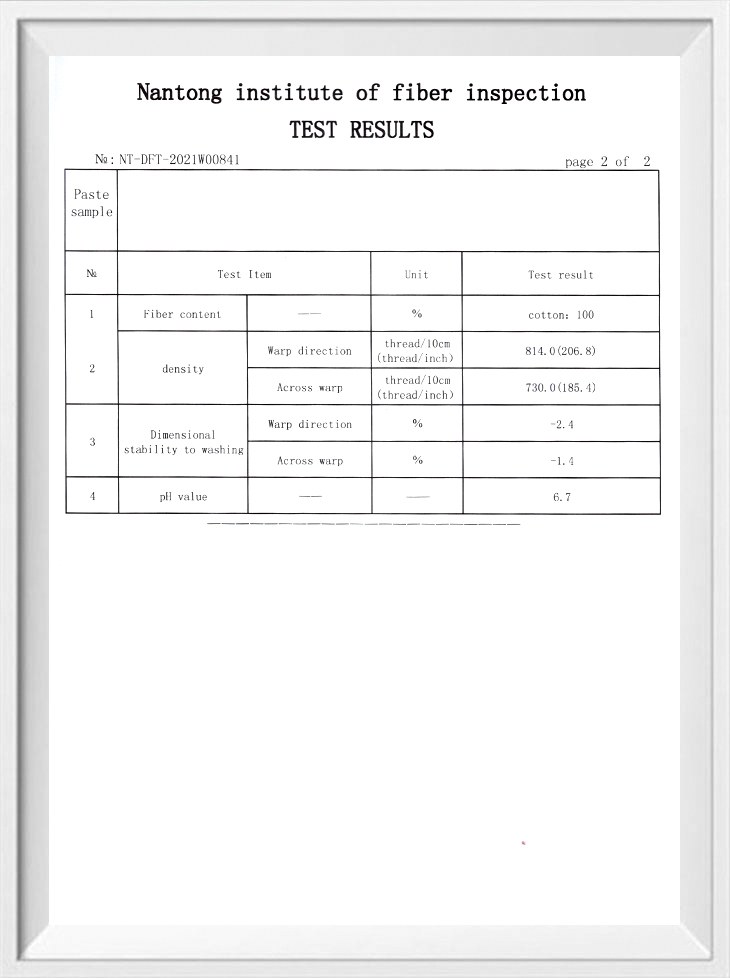

1. Reinforced structure: The quilting process can firmly stitch the various parts of the mattress protector together to form a stable overall structure. This prevents the mattress protector from becoming untied, deformed, or loose during use, and keeps its shape and functionality intact.

2. Improve durability: The quilting process uses wear-resistant stitches, combined with appropriate stitching density, to enhance the durability of the mattress protector. It effectively resists the friction and pulling of daily use, extending the life of your mattress protector.

3. Enhance stability: The quilting process can ensure that the filling of the mattress protector is evenly distributed, preventing the filling from shifting or accumulating during use. This helps keep the mattress protector flat and comfortable, improving your sleep experience.

4. Beautify the appearance: The quilting process can make the edges and joints of the mattress protector smoother and more beautiful, reducing the occurrence of threading, pilling and other phenomena. Fine quilting enhances the overall look and feel of a mattress protector.

5. Easy maintenance: Mattress protectors are usually easier to clean and maintain after they are made with meticulous quilting. The quilting process ensures that the mattress protector is not easily deformed or damaged during cleaning and maintains its good condition.

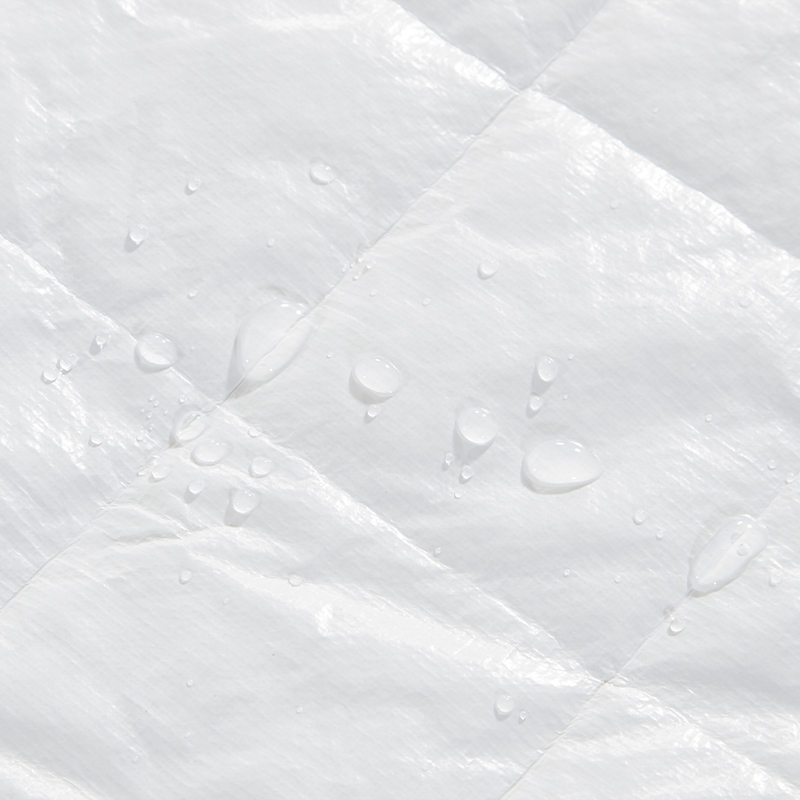

Waterproof Microfiber Woven Pillow Protector for Home and Hospital Use for Hotels Hotel pillow protector +

Waterproof Microfiber Woven Pillow Protector for Home and Hospital Use for Hotels Hotel pillow protector + Quality jacquard leaves cotton snow white bedding fabric hotel Hotel sateen jacquard bedding fabric +

Quality jacquard leaves cotton snow white bedding fabric hotel Hotel sateen jacquard bedding fabric +

EN

EN English

English русский

русский Español

Español عربى

عربى

Online Message

Online Message